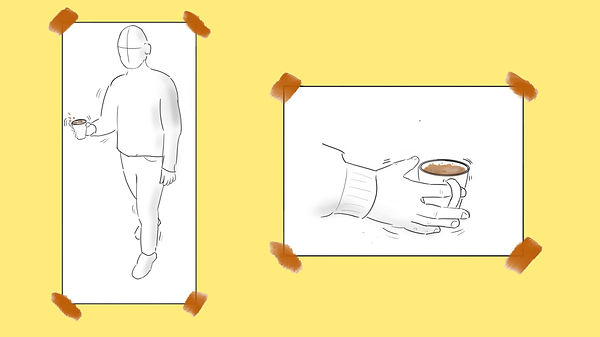

Final product

Design challenge

"Jack needs to be able to carry

a drink from A to B without spilling it"

Since the co-designer was diagnosed with Ataxia, it is hard for him to keep balance while walking. The co-designer needs to focus a lot on keeping balance, so it is difficult to carry a drink at the same time. While seating the problem does not occur since the upper body is still working well.

Product solution

The lid as shown in the storyboard and drawings is a universal solution for the co-designer to walk safely with a drink. The conical shape of the lid makes sure that the lid fits on multiple size mugs with an inner diameter ranging from 6 to 8,5 centimeters (note that this theory still needs to be tested). The grippers function as a clothing pin and make sure that the lid does not fall of the mug. Since the outside of the conical shape will be made from silicon, that will create the seal and the grippers make sure the seating position stays the same.

The conical shape of the lid and the design of the grippers in the opened position also function as a guide for the lid. Since the co-designer has trouble with his fine motoric movements, this design allows for easier application of the lid onto a mug. The storyboard shows the process of applying the lid, walking with the mug and lid and finally taking it off and placing the lid onto the table.

Detailing

Color

The co-designer wanted a black and orange color combination which also fits the style collage nicely. It gives a luxurious and premium feel to this product, which is exactly what the co-designer wanted.

Solidworks

The following pictures show the SolidWorks model that’s used for the creation of the final prototype.

Material choice

A material study is performed to choose a suitable material for a final mass produced product. Poly propylene (homopolymer, low flow) resulted to be the most suitable material according to Granta Edupack. Poly Propylene is often used in food or drink products and its melting point is at 160 degrees Celsius, more than twice the temperature in a dishwasher. Besides that, it is injection mouldable and recyclable, which makes it perfect for mass production. The outside of the conical shape which makes the seal with the mug should be silicon. The type of silicon is not yet chosen. The full document on material choice can be found here.